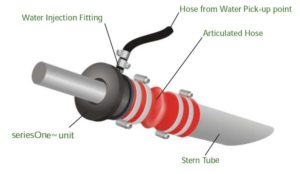

Designed for stainless steel propellor shafts for smaller boats, the SeriesOne® shaft seal by Tides Marine is available in 7/8″, 1″, 1 1/8″, and 1 1/4″ sizes. For metric applications, SeriesOne® is available in 22mm, 25mm and 30mm sizes.

The SeriesOne® shaft seal is available for single engine applications only. For Twin engines, the SureSeal® is the product of choice.

Key components/features of the new SeriesOne® include:

Housing:

A one-piece body of complex composite material which allows the bearing surface to provide long life and a stable performance platform for the lip seal. The body material does not absorb water and is temperature resistant.

Bearing:

A unique structure in the shaft body design has the body and bearing of the same material. From concept to reality, this design affords the boat owner a reliable, durable, component at the price of an “old fashioned” packing seal.

Hose-

Matched to various service demands, there are options which will add life to your SeriesOne® seal simply by identifying the application environment. For competition ski boats or other crafts with short shafts, high RPM, and solid, tight engine mounts, the single convolutedhose is suggested. For work boats with softer engine mounts, small diesel engine applications such as on sailboats, or other shafts that exhibit more lateral movement during operation, the multi-articulated hose is recommended.

Hose Clamps-

Standard clamps, two per side as prescribed, will suffice. Should your intended use be in an extremely harsh environment, an upgraded clamp style is available.

Seal Replacement-

If in-water replacement is a desired option, please use our SureSeal® line of self aligning shaft seals. Spare seal carriers containing spare lip seals are available only for SureSeal® units. The SeriesOne® seal is designed to be removed and replaced when the useable lifespan has been achieved.

Limited Warranty- Should your SeriesOne® shaft seal not perform to your expectations, contact Tides Marine for a return authorization within one year of purchase. Return the entire unit along with proof of purchase, to receive a replacement.

SPECIAL NOTE FOR PDQ MV34: Tides Marine Shaft Seal Assemblies may be installed at the owners discretion, but will be supplied WITHOUT Warranty.

Installation Overview

The following is a brief description of a typical SeriesOne® installation. Detailed instructions are included with each product and should be followed closely.

USE NO GREASE!

1. Remove shaft from transmission coupling.

2. Disassemble and remove existing shaft sealing system if applicable.

3. Remove the hose clamps and old hose from the shaft log (stern tube). Discard Them. DO NOT RE_USE these components as they will not function correctly with the SeriesOne®.

4. Draw the shaft back up against the coupling. This will expose that portion of the shaft that was located under the old hose and stuffing box.

5. Insert the end of the SeriesOne® unit into the articulated hose and push in as far as it will go.

6. Position the hose next to the stern tube to determine approximately where the lip seal will ride on the shaft.

7. Examine this area carefully. Be sure that it is free of pitting, nicks or surface imperfections that could cause leaking. Clean this area thoroughly. Polish the shaft using 300 grit wet/dry sandpaper or emery cloth working around the shaft. Fore and aft actions could put flats or grooves in the shaft. In order to find the best spot to position the lip seal, may be shifted forward slightly by adjusting the position of the hose on the stern tube at time of installation.

8. Carefully press the red seal protector “hat” into the front of the SeriesOne® unit. Make certain it covers the “lip” portion of the seal.

9. Back the shaft away from the transmission to provide enough room to install the assembly.

10.Carefully slide the assembly (hose-end first) onto the shaft so that the shaft passes through the red seal protector “hat”.

11.Slide the assembly down the shaft and onto the stern tube. Push it on as far as it will go or as needed to position the lip seal on the shaft at a clean spot.

NOTE: Ensure that both clamps will clamp the stern tube.

12. Reconnect the shaft to the shaft coupling. Make certain the shaft coupling is firmly secured to the transmission.

13. To help align the unit, grasp theassembly and slide it forwards on the stern tube an inch or so and rotate it side to side twice. Slide the assembly back into position on the stern tube. Space the two hose clamps over the stern tube end evenly and “snug”. Hose clamp screws should be on opposite sides to distribute the pressure evenly. Space the two clamps on the SeriesOne® end of the hose evenly and “snug”. Confirm that both the SeriesOne® shaft seal and stern tube are fully inserted into the articulating hose. Tighten all four hose clamps.

14.Pull the seal protector from the SeriesOne® shaft seal. Seperate the tabs to split the cone and remove it from the shaft.

15.Connect the SeriesOne® shaft seal to a pressurized water supply source (point in the engine’s raw water cooling system) by attaching the water injection hose to the brass fitting on the housing. At idle speed, water should be flowing at 1 gal/4 l. per minute. Check rate by timing flow into an empty container.

CHECK WATER SUPPLY BEFORE OPERATING VESSEL

DID YOU REMOVE ALL THE RED SEAL PROTECTOR “HATS”?

Before Ordering

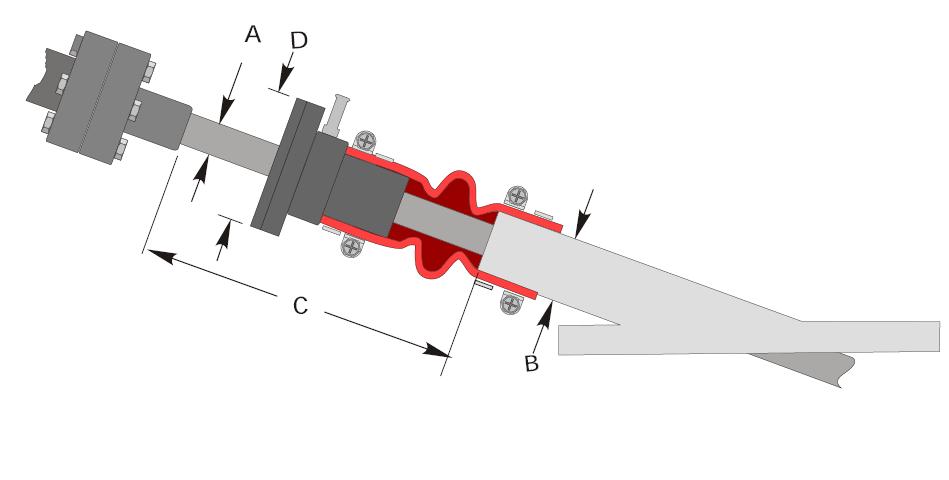

SeriesOne® shaft seals are sold with their corresponding hoses only. To determine which parts to order and whether or not you have sufficient space for their installation, you need to measure “A”, the shaft diameter and “B”, the O.D. of the stern tube (which corresponds to the hose I.D.). Find the combination of these two dimensions in the following table and the corresponding part numbers. For each model SeriesOne®, find dimension “C” and confirm that there is AT LEAST this much CLEAN, SMOOTH shaft before the stern tube available for locating the unit.

Next, the diameter “D” should be noted. Confirm that a minimum distance of 1/4 inch can be maintained between the body of the unit and any other part of the boat (hull, stringers, etc.) to allow for any lateral shaft movement.

Builders Note:

SeriesOne® Shaft Seals are sold as complete kits which include Seal, Hat, Articulating Hose and ABA/ AWB Clamps.